浙江金石制药设备有限公司客服热线:0579-87644516

FLG型流化床制粒机

应用范围

流化床制粒机是制药/食品领域广泛应用的固体制剂生产工艺流程的设备之一,主要用于 片剂、胶囊、冲剂等剂型的颗粒生产,是制粒、粉末混合和干燥工艺的理想选择。 精准的工艺参数控制是金石新型流化床处理器的关键特性。基于专利技术的简化加工理 念,以及符合GMP的紧凑设计,以提高效率并完全符合当前行业需求。 它与其他造粒设备很容易集成,与固体剂量处理线无缝对接。FLG是最灵活的流化床设 备,允许不同类型的工艺之间柔性切换:干燥工艺/制粒工艺。 制粒(顶喷) 该设备保证了相同设备中批量处理的工艺一致性、灵活性。FLG设计用于穿墙安装,简 化了与其他加工设备的集成,如湿法制粒机,物料传输设备等,从而减少了生产操作的 空间要求。

Applications

Fluid bed granulator is one of the equipment of solid preparation production process commonly used in the pharmaceutical industry. It is mainly used in the production of tablets, capsules, granules and other dosage forms. It is an ideal choice for granulation, powder mixing and drying process. Precise parameter control is the key features of JINSHI’s new fluid bed processor. Simplified processing concepts based on patented technologies together with compact GMP compliant design for greater efficiency and to fully respond to current industry requirements. Easily integrated with other granulation equipment, It fits seamlessly into solid dose processing lines. FLG is the most flexible fluid bed equipment allowing different types of processes: Drying Granulating (top spray) Additionally, the machine guarantees a large flexibility of batch size processing in the same equipment. Designed for through-the-wall installation, FLG simplifies the integration with other processing equipment, such as wet granulators, product conveyors, thus reducing space requirements in the production room.

产品特点:

1、穿墙设计使得设备布局简洁,节省生产区域的设备安装空间。

2、根据不同的工艺要求(制粒、干燥)可更换不同的气流分布板,实现制 粒的均匀和干燥的高效性。

3、流化床各腔体之间采用充气密封,不采用底锅气缸顶升的密封方式,密 封方式更有效,更安全。

4、顶部过滤袋的除尘采用脉冲反吹方式,滤袋按设定时间依次抖袋除尘, 保证了抖袋的连续性和气流的稳定性。 滤袋更换方便。只更换破损的滤袋即可,不用大面积拆除滤袋,节约更换 时间。

Features:

1.The through wall design makes the equipment layout simple and saves the equipment installation space in the production area. 2.According to different process requirements (granulation and drying), different air distribution boards can be replaced to achieve the uniformity of granulation and high efficiency of drying. 3. The expansion seal rings are adopted between the chambers of the fluid bed. It does not use the sealing mode by cylinder lifting bottom bowl, so the sealing mode is more effective and safe. 4.The top filter bags adopt pulse blowing method for dust removal. Shaking the bags in turn according to the set time to ensure the continuity of shaking bag and the stability of air flow. 5. It is convenient to replace the filter bag. Only the damaged filter bag can be replaced without removing the filter bag in large area, saving the replacement time.

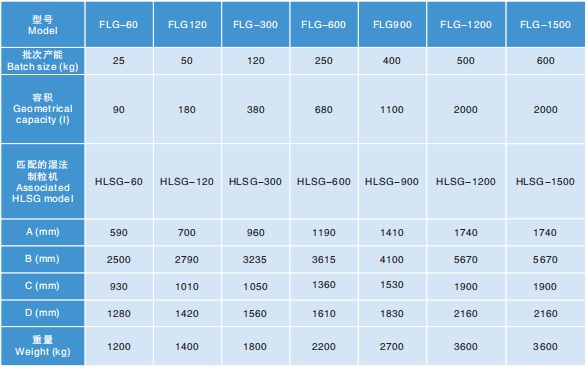

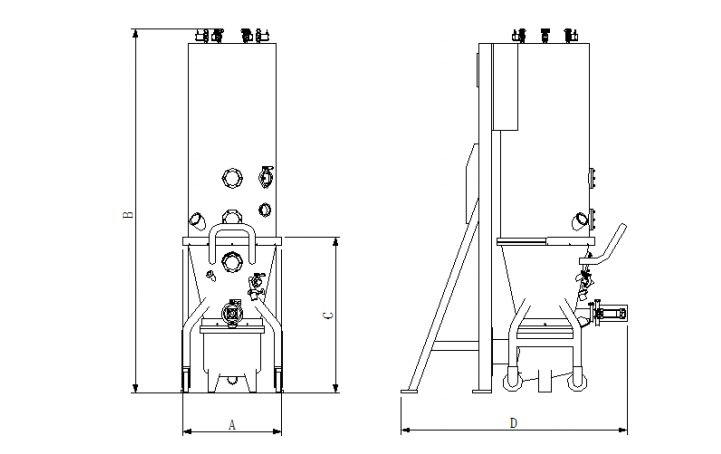

技术参数(Technical paramenters):