浙江金石制药设备有限公司客服热线:0579-87644516

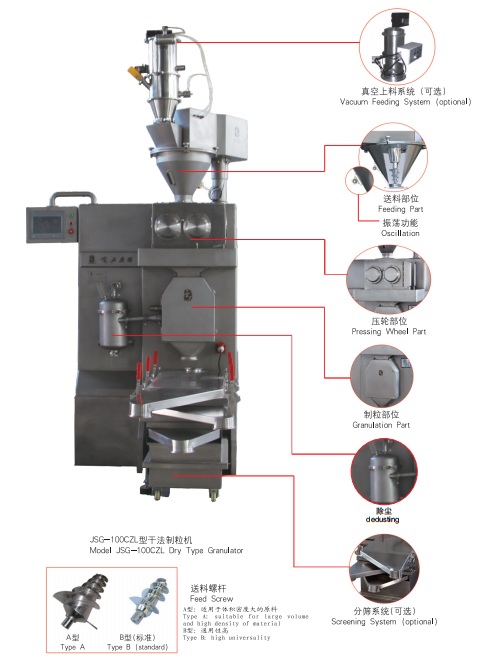

JSG-100立式干法制粒机工作原理(Working Theory of Dry TypeGranulation Facility):

根据机械挤压造粒工艺原理,将配置好的,具有一定结晶水的干粉状或微细晶体状原料,挤压成薄片,后经造粒系统,通过筛网制成所需大小的颗粒。

原料可通过手工上料或真空上料机加入料斗,经送料螺杆输送和压缩.被推至两挤压辊轮的咬入角:通过压辊,将原料挤压成薄片。物料所需的压力通过液压装置线性传送给压辊,液压装置可保持一定的预压力, 垂直排列的压辊可保证物料密度的一致性。根据不同颗粒度要求,设备造粒系统中的筛网目数大小可相互更换。

According to the technical theory ofmechanical extrusion for granulation, a wel-prepared powdery or finely crystallinematerial with crystal water is laminatedand made into particles of required size bymeans of screen in the granulation system.

The material may be fed into the bucketby hand or vacuum feeder, conveyed andcompressed in the feed screw, and pushedinto bite angle of two extrusion wheels.The material is laminated by therollers.The pressure required by material islinearly delivered from hydraulic device torollers. The hydraulic device can maintaincertain pre-pressure and the verticallyarranged rollers can guarantee theconsistent density of According to different required grainmaterial.sizes, the screens with different meshes inthe granulation system can be interchanged.

JSG-100立式干法制粒机干法制粒优点(Advantages of Dry TypeGranulation):

将粉体或微细晶体原材料直接制成满足用户要求的颗粒状产品,无需任何中间体和添加剂,造粒后产品粒度均匀,堆积密度显著增加,改善流动性,既控制'了粉尘飞扬,又减少粉料浪费。便于贮存和运输,可控制溶解度、孔隙率和比表面积等。

本机在湿式造粒法中难生产的抗生物质。胶囊填充用颗粒及制造药片的造粒上能发挥很大的作用。

Powder or fine crystal can be directlymade into granules to the satisfaction ofusers, without requiring any intermediate oradditive. The granules have even grain sizewith considerably increasing bulk density.This can improve the fluidity, inhibit theraised dust and reduce the waste of powder.

It is easy to store and transport andallows the control of solubility, porosity andspecific surface area.The granulator generates the antibioticThe granulator generates the antibiotictype granulation. .type granulation. .It can play an importantrolein thein thethe granulation for pills.

JSG-100立式干法制粒机应用范围(Applcability):

在制药工业中,广泛涉及到对各种活性的药品原料以及-种或多种赋形剂的加工处理。这些原料药大部分是细的粉末,并且这些粉末粒径大小不一,密度不匀,流动性差,易分层。这些原料药必须经过制粒工艺处理.才能.被用于压片、胶囊填充或其他药物加工工序。干法制粒因其具有多种优势.特别适用于在湿.热条件下不稳定的药物的制粒。

The pharmaceutical industry oftenprocesses the medicine materials of variousactivities and one or several excipients.Most of bulk drugs are finely powdery indifferent grain sizes, uneven density, poorfluidity and easy stratification. They must begranulated before being laminated, flled intocapsules or processed in other ways. Forits various advantages, dry type granulationis particularly suitable for the granulation ofdrugs unstable under wet and hot conditions.

JSG-100立式干法制粒机特别说明(Special Note):

在产品设计和生产过程中,我们遵循了美国FDA、GMP思想。任何一台设备在生产过程中,皆具备GMP控制范围;在设计过程中,任何一台设备皆在GMP内创新构思。所有的非金属材料均符合GMP &FDA标准。

送料量、压力、压辊间隙、片厚、整粒间.隙、片硬度等工艺参数通过逻辑运算、数理统计建数据模型,并形成科学系统关系。

In the machine design and .manufacturing process, we follow theFDA GMP idea. Any equipment in themanufacturing process has GMP controlrange,In the designing process, anyequipment is in GMP innovation concept.All non-metallic materials comply withGMP&FDA standards.

The process parameters such as feedamount,pressure roller gap, slicethickness,grinding gap and slice .hardness were established to formscientific system relationship throughlogical operation and mathematicalstatistics.

JSG-100立式干法制粒机设计特点(Design Features):

1、压轮及压轮座为外露式结构设计;

2、工艺处理装置可快速拆卸,以便生产设施外进行清洁和灭菌处理;

3、制粒过程在精密的制粒装置中完成,先进的制粒系统.独特的制粒构造设计,使生产成品率大大提高.减少了二次回料加工.提高生产产品质量与产量;

4、生产过程的控制和确认可通过PLC操作程序执行或手工操作控制执行完成;

5、压轮表面经气体渗氮处理,具有较强的耐磨性和抗疲劳强度,且具有较好的抗腐蚀性;

6、侧密封板通过丝杆定位调节,延长侧密封板的使用寿命;

7、整机自带水冷却循环系统,保证压轮在使用过程中的温度得到控制.防止物料在压制过程中因受热而粘结、变色.变质;

8、液压系统通过电控调节控制.无需手动开启压力表开关操作;

9、根据物料特性。选择压缩轧辊与送料螺杆得到分布均匀颗粒;

10、作业性.安全性优越,可符合GMP要求;

11、无需添加润滑剂.也能成型;

12、振荡功能设计.防止物料吸附.增强物料流动性;

13、打印功能设计.便于打印不同配方颗粒数据及类别区分。

1、Pressing wheel and its base are designedin anexposed structure;

2、The processing device can be rapidlydetached to facilitate the cleaning andgermicidal treatment outside the faciliy;

3、The process of granulation is completedin the delicate granulation facility. Theadvanced granulation system and uniquegranulation design considerably improvethe rate of finished products, reducethe processing of recycled material andenhance the quality and yield of products;

4、The control and verification of productionprocess can be performed by PLC .operating program or manually;

5、The pressing wheel surface receivesthe gas nitriding treatment to obtain highwearing quality and fatigue resistance aswell as good anticorrosion;

6、Side sealing board is positioned andmodulated by screw to elongate itsservice life;

7、The unit is equipped with water coolingcirculation system to guarantee thetemperature of pressing wheel undermaterial from caking, discoloringand deterioration in the process ofcompression.

8、The hydraulic system is manipulatedelectrically without manually turning onpressure gauge.

9、The hydraulic system is manipulated letrially withoutmanually turmning on pressure gauge.

10、The compression roller and feed screw are selectedaccording to the nature of material to evenly distrbutethe granules;

11、The operation perormance and safety are outstandingand meet the GMP requirements;

12、Forming can be performed without adding lubricant;

13、The design of oscillation can prevent the absorption ofmaterial and increase the fluidity of material.

JSG-100立式干法制粒机技术参数(Technical Parameters):

生产能力

●生产处理量: 100Kg/h (以食用玉米淀粉为例)

●可成型粒度: 0.2-2 mm(更换筛网调节)

● 油泵:电动加压;

●成型压力: 40T

● 安装功率: 12.5KW

●整机重量: 1600kg

●外形尺寸:1250x1230x2250(mm)

●压轮大小: 208x78 (mm)

●料架升降:液压升降

●物料接触部分材质:SUS 304 &316L

●挤压轮材质:2Cr13、3Cr13、合金钢

●与产品接触的径向轴密封圈: PTFE/氟橡胶

●Production capacit: 100kg/h (dependingon the nature of material)

●Grain size: 0.2-2mm

●Oil pump: electrical

●Maximum forming pressure: 40T

●Installation power:12.5KW

●Dead weight: 1600kg

●Dimension:1250x1230x2250(mm)

●Size of pressing wheel:208x78(mm)

●Rack elevation: hydraulic

●Material: SUS 304 & 316L

●Material of roller: 2Cr13、 3Cr13、 alloy steel

●Axial gasket in contact with product:PTEF/fluorubber